The new material of automobile new material, | Shanghai jiaotong research and development ceramic aluminum alloy new material

1. Shanghai Jiaotong University developed a super-nano ceramic ceramic new materials

Aluminum can "long" ceramic? Recently, the Shanghai Jiaotong University School of Materials Science and Engineering Professor Wang Haowei led the scientific research team gives the answer: they let the aluminum "long" out of the ceramic. This is named super-nano ceramic ceramic "Hercules" strength and stiffness can be more than titanium, but the weight is the metal family of lightweight. Experts predict that nano-ceramic aluminum will lead to aviation, cars, high-speed rail into the lighter, more energy-efficient new material era. (Light daily)

2. The company has won the "AltairEnlightenAward" award in 2017 for HSA's high-strength automotive aluminum alloy HSA6

According to foreign media reports, the company has developed a new generation of high-strength 6000 series aluminum alloy -ConstelliumHSA6, designed to meet the growing demand for lightweight aluminum. For collision management systems, white body structures and battery housings, the Constellium HSA6 aluminum alloy is a very desirable material for designers to optimize extrusion and reduce their wall thickness. Compared to traditional aluminum alloy, Constellium HSA6 aluminum alloy can achieve weight loss of 15-30%. In addition, subsection aluminum alloy material can enhance the strength of 15-30%, can enhance the protection capacity of the vehicle in the event of a collision, to strengthen the defense capability of the battery, helping to cool the battery system and other critical vehicle systems. The aluminum can also absorb kinetic energy at the time of the collision, providing protection for car users and pedestrians to maximize vehicle integrity. (Geshi)

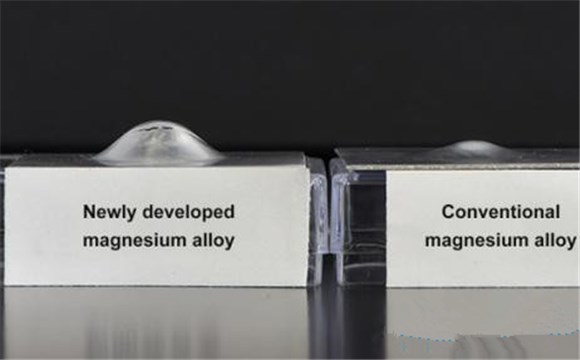

3. Japan to develop high-strength magnesium alloy parts of the future or will be used for body parts

According to foreign media reports, the National Research Institute of Materials and Materials (NIMS) research team and the National Nagaoka University of Science and Technology (NagaokaUniversityofTechnology) jointly developed a new high-strength magnesium alloy plate (Mg-1.1Al-0.3Ca-0.2Mn- 0.3Zn). Compared to some of the current car body sheet metal parts used by aluminum sheet (aluminumsheetmetal), its molding performance at room temperature is quite good. After heat treatment, the magnesium alloy strength is higher than the aluminum alloy, which only uses a common metal material, the future or will become a low-cost lightweight automotive sheet. (Car lightweight online)

4. Carbon fiber reinforced composite material preparation - for the lightweight design of technological innovation

Carbon fiber composites give engineers almost unlimited design blindness, as a class of innovative design methods, especially for the development of lightweight products have great significance. However, the performance of various composites has so far not been comparable to the high load-bearing properties of carbon fiber composites. CIKONI (Germany Stuttgart) composite materials company first through the combination and fully automated manufacturing methods designed carbon fiber composite structure, in which continuous carbon fiber reinforced fiber fiber direction and load path consistent with carbon fiber as a base structure, used to support the compression load. Carbon fiber reinforcements eliminate the limitations of these two technologies by 'target hybridization': not only reduces the waste of material produced by 3D printing components, but also eliminates the need for separate tooling in the robot manufacturing process. Therefore, there is a positive impact on the cost. (Car lightweight online)

5. Cobalt prices soared to force nickel to replace the electric car battery just needed

Cobalt prices soared, prompting major Asian battery manufacturers to change the ratio of raw materials for electric vehicles and cell phone batteries, reducing the amount of cobalt, while increasing the nickel content. It is expected that by 2025 years, the battery demand for electric vehicles will jump 19 times, manufacturers seeking to reduce the battery in those more expensive ingredients. Cobalt prices have more than doubled in the past year, due to strong demand and supply shortages. UBS said in a recent report that the demand for electric vehicle batteries is expected to increase by 10-40% from now to 2025, depending on how much nickel can replace cobalt. (Minnan network)

6. Greenmeal 900 million yuan capital increase Jingmen subsidiary overweight circular economy and new energy materials

August 2 evening, Grammy (002340) announced that the company will own funds 900 million yuan capital increase wholly owned subsidiary Jingmen Green, to further expand its existing business. Greene said that this Jingmen Green Mei capital increase is conducive to meet the Jingmen Green US development needs of the liquidity needs, and further expand its existing business, enhance the company in the circular economy and new energy materials industry, the overall strength and profitability. (China battery network)

7. South Steel first single overseas M & A: lightweight to enhance the quality of the car, the layout of new materials, energy and environmental protection

"Going out" is to "come" better. August 2, Nanjing, Nanjing Iron & Steel United Co., Ltd. (hereinafter referred to as the Dragons) using its own funds to complete the acquisition of the controlling German automotive lightweight solutions provider Kohler Co., Kohler became the first car in the holding Fosun system Supplier business. This transaction is the first single overseas steel mergers and acquisitions. (Intersection)

8. Steel PK Aluminum who will occupy the dominant position of the car lightweight

According to foreign media reports, and now the major car prices have continued to increase material research and development costs, aimed at research and development of new alloys and materials, while enhancing its performance. In addition, car prices have also improved their latest welding and forming technology, for the production of various materials and alloys to provide support. Such inputs have the same goal: to reduce emissions while achieving light weight. As the automotive industry will meet the increasingly stringent emission standards, the best way to deal with is undoubtedly reduce the weight of the body (lightweight). To this end, the need to combine the use of various types of aluminum and high-strength steel, magnesium, composite materials (such as: carbon fiber) and various types of plastic. Future aluminum will dominate the timber used in large vehicles (SUVs, trucks, pickups), while advanced high-strength steels will dominate small vehicles. (Geshi)

9. High-end consumer demand to promote the automotive interior materials market

For consumers, the car interior parts of the beauty, comfort, noise reduction performance is becoming increasingly important. According to CoherentMarketInsights (Seattle) the latest release of a report to 2024, the global automotive interior materials market will witness a huge increase. Coherent pointed out that in this growing market, car manufacturers need to provide a high level of customized services to meet the needs of consumers, the use of high-end consumer purchasing power. "So far, more and more consumers tend to buy cars with premium car characteristics," the analysis said. The increase in vehicle lightweight requirements also drives manufacturers to pay more attention to the right interior materials. (In plastic online)

10. Mercedes-Benz for the first time using 3D printing to produce metal parts

Recently, from the overseas media was informed that Mercedes-Benz (mercedes-benz) in the manufacturing transformation has taken an important step: the use of 3D printing technology to produce metal parts. Not only that, Mercedes-Benz said that the link passed all the rigorous quality tests. With the development of technology, Mercedes - Benz envisioned a future. In this future, special parts can be quickly copied, for the classic models to create a higher standard. After the assembly line is closed, the 3D printer can make the production of rare or unknown automotive parts easier. Another benefit is that the warehouse's storage and complex transportation will be almost eliminated by the on-demand 3D printing of mechanical components. (Car network)

11. Toyota released solid-state battery plan, called Tesla

Last week, Toyota released the news, plans in the early 1920s to achieve all-solid-state battery commercialization. All-solid-state battery promotion, will replace the current lithium-ion battery widely used liquid electrolyte technology. According to the Japanese media reported that equipped with all solid-state battery Toyota electric car will be the first in 2022 listed in Japan, when the completion of a charging process will be shortened to a few minutes. Toyota's all solid-state energy storage battery, the current mainstream of the three yuan lithium-ion battery is undoubtedly a declaration of war. Toyota is also the first breakthrough plan for the design of the Tesla vehicle design problem, Toyota announced in this area. (omnipotent)

12. Mazda Chong Chi blue sky engine upgrade for the second generation using homogeneous inflatable compression ignition HCCI technology

According to the US media reported on August 6, Mazda launched the second generation of flash blue sky (SkyActivII) engine, using a new ignition technology - homogeneous inflatable compression ignition (HCCI), the overall fuel efficiency increased by 30%, the engine will be in 2017 In late August the Frankfurt Motor Show debut. Mazda will launch a new non-spark engine HCCI homogeneous pressure combustion combustion technology, the working principle and the diesel engine is similar to the need for spark plugs fuel gas mixture, by compressing the air and fuel mixture in the cylinder until it burns, but still use gasoline As fuel. Moreover, the engine will be in the low speed range to retain the spark plug ignition, and in the high speed range switch to homogeneous compression combustion mode. This design can reduce emissions, while enhancing power and fuel economy. HCCI homogeneous pressure burning combustion technology will be used in the second generation of Chi-blue sky (SkyActivII) engine. (Automotive industry concern)

13. Volvo reverse black technology, glass fiber instead of spring, plate hanging play a new height

Volvo has released a new XC60, as the new Volvo XC60 made the biggest change, in addition to the platform changes, is the body behind the bold innovation. The front suspension for the double wishbone independent suspension, emphasizing the safety and control sense, and although the rear suspension for the multi-link independent suspension, but the original has been abandoned for decades has been used in the coil spring structure, turn And the use of the ZF provided by the glass fiber elastic sheet, this design can be described as quite bold. (A car exchange)

14. graphene reinforced rubber tire strength increased by 50%

Graphene has the characteristics of optimized carbon fiber, its thermal function and mechanical strength also has outstanding performance, this material applied to the tire, rolling and slippery performance than ordinary tires have significantly improved, especially the tear resistance with the Very high lift, graphene in the tread on the high strength of the realization of rubber modulus, tensile strength increased by 50%. At present, Sen Kirin, Delicate, Double Star and other manufacturers of related products have been available, I believe that in the near future, graphene tires are expected to face consumers. The tire shop will be a new way of profit. (Car and round)

15. 100 Knight invested 300 million yuan to build polyurethane environmental tire factory

High wear resistance, anti-puncture, green, colorful, a new type of environmentally friendly tires will be in the new manufacturing. Reporters recently in Xinxing County, a new industrial park interview learned that the 100 Knight (emerging) New Materials Technology Co., Ltd. Polyurethane environmental protection tire manufacturing project is continuing force, leasing plant production line recently trial production, the new plant project is also tight gong tight Drums in advance. This new type of green tire with high wear resistance, anti-puncture and other characteristics, the company launched for mine, port oil field and other special places of use of polyurethane filled with solid tires, anti-corrosion tires and polyurethane tires, etc., to fill and refresh the history of tire manufacturing Of the blank, the market prospect is broad.